|

|

- I'm Online Chat Now

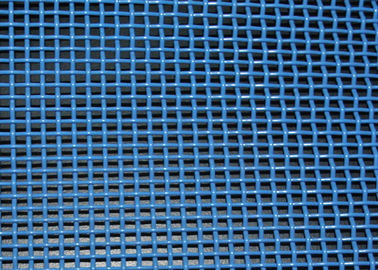

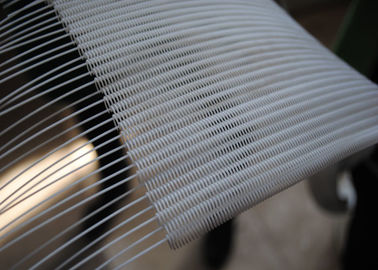

polyester dryer screen

Hard Wearing Polyester Dryer Screen Mesh Fabric for Coal Mine Sieving

Discription of Polyester Dryer Mesh Screen is also used for tailings disposal,colliery,food and medicine:

1. the opening size can be 400 micron,500micron,600micron,700micron,800micron,1000micron,1500micron,1800micron,2000micron,2500micron and 3000micron.

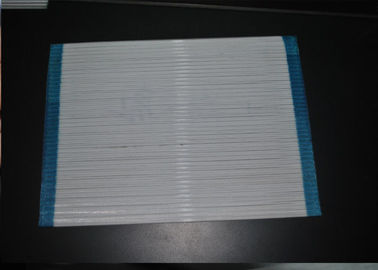

2. the width of polyester dryer screen mesh is usually 1 meter - 6 meter,the length is available as per requirement

3. edge treatment:the edge of polyester mesh dryer belt can be sealed with glue and cavans

To make sure extra belt durability,polyester Dryer Screen mesh edge treated with glue and cavans.

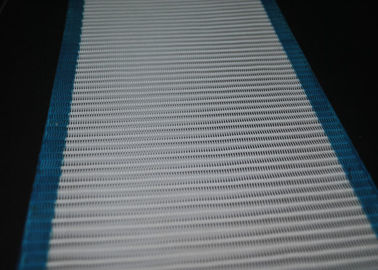

4. the joining type of 05802 polyester mesh Dryer belt can be endless,steel pin joining,spiral ring joining and pin ring joining.

Endless Seam make sure the seaming points has the same airpermeabilty and strength with the whole belt

Steel pin,pin ring and spiral ring seam are designed for easy and rapid installation.

Tech Datas of Polyester Mesh Belt Screen Fabric

| Polyester Mesh Belt Dryer Screen | |||||||

| Weaving Type | Model | Thread Diameter | Density(No.s/cm) | Srength | Air Permeability | ||

| (mm) | (N/cm) | (m3/m2h) | |||||

| Warp | Weft | Warp | Weft | ||||

| 2-shed plain weaving fabric | 5802 | 0.75 | 0.8 | 4.7-5 | 4.8-5 | 940 | 20000 |

| 5102 | 1 | 1 | 4.7-5.2 | 4.3-5 | 1600 | 15000 | |

| 6702 | 0.7 | 0.7 | 8 | 7 | 1600 | 11000 | |

| 7102 | 0.7 | 1 | 6.6-7 | 4.3-4.6 | 1100 | 15000 | |

| 8552 | 0.55 | 0.55 | 7.5-8 | 8.5-9 | 850 | 850-6500 | |

| 9452 | 0.45 | 0.45 | 10 | 8.6 | 1600 | 16000 | |

| 9502 | 0.5 | 0.5 | 8.5-9 | 10-10.5 | 750 | 10000 | |

| 12502 | 0.5 | 0.5 | 13.5 | 8.5 | 1800 | 6500 | |

| 3-shed plain weaving fabric | 8603 | 0.5 | 0.6 | 10 | 9 | 1600 | 14000 |

| 8903 | 0.9 | 0.9 | 7.8-8 | 5-5.5 | 2100 | 7500-8500 | |

| 7803 | 0.7 | 0.8 | 8 | 8 | 1600 | 10000 | |

| 20353 | 0.3 | 0.35 | 22 | 14.5 | 1200 | 13000 | |

| 20403 | 0.3 | 0.4 | 22 | 14.5 | 1200 | 13500 | |

Durable Polyester Dryer Screen Sludge Dewatering Mesh Belt For Water Treatment

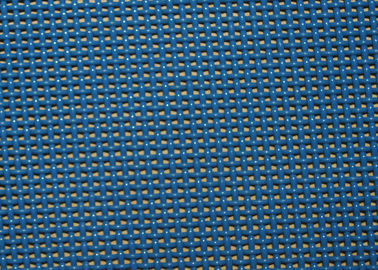

Description of polyester dryer screen

Polyester spiral dryer belt is using the latest international in the ninety s made of nonwoven technology and equipment production, is currently the world's one of the most advanced drying, filtering material. I plant the production of polyester spiral stem network is made of high quality high viscosity polyester chip processing wire, after forming, weaving, finishing, finalize the design.

Application of polyester dryer screen

- Municipal life sludge

- Widely used in paper-making,coal mining,food,pharnaceutical,printing and dying,rubber industry.

- Conveyor belt and composite machine mesh belt filter.

Specification:

| Polyester Spiral Dryer Conveyor Wire Mesh Belt | ||||

| Weaving Type | Model | Thread Diameter | Air permeability | |

| (mm) | (m3/m2h) | |||

| Warp | Weft | |||

| Large Loop | 4070 | 0.9 | 1.1 | 20000±500 |

| Medium Loop | 3868 | 0.7 | 0.9 | 18500±500 |

| Small Loop | 3252 | 0.52 | 0.7 | 15000±500 |

Features:

- Smooth,seamless filter or conveying surface.

- Durability,Stable property, high strength,good cake release.

- Heat-resistance,high temperature resistance(180 degree).

- Shrink-resistant,wear resistance, acid and alkali-resistant.

- High dimensional and diagonal stability,good air ventilation.

- Filled or unfilled to achieved differing filtration characteristics.

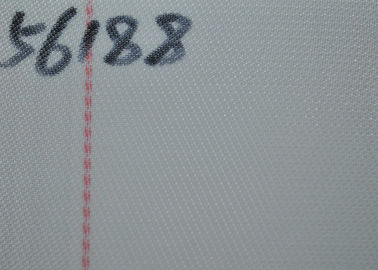

100% Polyester Dryer Screen Mesh Fabric Double Layer for Papaer Making

Polyester Mesh Fabric Layer Fabric classification:

Paper making Polyester Mesh Fabric Layer Fabric can be divided into 4-shed, 5-shed, 8-shed, 16-shed, 24-shed according to the weaving type. Single layer, double layer, two-and a half layer fabric and triple-layer fabric are the three common Items.

8-shed double layer polyester mesh fabric is suitable for producing quality printing paper. For example ,dictionary paper, offset printing paper, newsprint and wrap paper. It can be used for tissue paper making and the surface pulp, lining pulp, core pulp and bottom pulp of the board paper etc. Suitable for medium and high speed paper making machine.

4-shed and 5-shed series single layer polyester forming fabrics mesh belt are the two widely used polyester forming fabric in paper making, mainly used for producing cultural paper (single glue, double glue and color glue), printing paper, glazed paper, packing paper, common newsprint. Suitable for common fourdrinier paper machine.

8-shed single layer polyester mesh screen belt is suitable for kraft paper, cardboard , corrugated paper making. Also could be used for producing common printing paper. Suitable for common fourdrinier paper machine.

16-shed double and a half layer polyester forming mesh belt fabric is suitable for producing quality printing paper, such as offset printing paper, copper plate paper, newsprint and cigarette paper series (wrap paper and filter tips paper), Also is could be used for producing toilet paper, tissue paper and surface pulp, lining pulp, core pulp and bottom pulp of the board paper etc. Suitable for medium and high speed paper making machine.

Multi-shed three-layer polyester fabric is suitable for producing quality printing paper, tissue paper and cigarette paper etc. Suitable for high speed paper making machine.

Specificaitons of paper making polyester dryer screen:

| polyester forming fabric for paper drying | |||||||||

| Weave type | Model |

Thread diameter (mm) |

Density

(NO./cm) |

strength (N/cm) |

Thickness (mm) |

Air permeability (APm³/m²h) |

|||

| warp | weft | warp | weft | ||||||

| 4-shed single layer dryer screen | 27254 | 0.2 | 0.25 | 30 | 22 | ≥600 | 0.49 | 8000 | |

| 27254-1 | 0.2 | 0.25 | 30 | 23 | ≥600 | 0.495 | 7500 | ||

| 27254-2 | 0.2 | 0.25 | 30 | 24 | ≥600 | 0.50 | 7000 | ||

| 27274 | 0.2 | 0.27 | 30 | 21.5 | ≥600 | 0.51 | 7800 | ||

| 27274-1 | 0.2 | 0.27 | 30 | 22.5 | ≥600 | 0.515 | 7300 | ||

| 31204 | 0.18 | 0.2 | 35 | 28 | ≥600 | 0.43 | 7500 | ||

| 31201-1 | 0.18 | 0.2 | 35 | 30 | ≥600 | 0.43 | 7000 | ||

| 31204-2 | 0.18 | 0.2 | 35 | 30.5 | ≥600 | 0.43 | 6500 | ||

| 5-shed single layer dryer screen | 28205 | 0.2 | 0.2 | 30 | 27.5 | ≥600 | 0.46 | 6800 | |

| 30205 | 0.17 | 0.2 | 32 | 28.5 | ≥500 | 0.41 | 7100 | ||

| 30175 | 0.17 | 0.17 | 32 | 29.5 | ≥500 | 0.39 | 6600 | ||

| 31215 | 0.2 | 0.21 | 35 | 32 | ≥600 | 0.48 | 7000 | ||

| 8-shed single layer dryer screen | 25358 | 0.22 | 0.35 | 28 | 19.5 | ≥700 | 0.85 | 9000 | |

| 25388 | 0.22 | 0.38 | 29.5 | 19 | ≥700 | 0.87 | 8500 | ||

| 27358 | 0.22 | 0.35 | 29 | 20 | ≥700 | 0.85 | 8500 | ||

| 27388 | 0.22 | 0.38 | 31.5 | 19 | ≥700 | 0.87 | 8000 | ||

| 7-shed double layer dryer screen | 50207 | 0.2 | 0.20/0.22 | 54.7 | 36.6 | ≥800 | 0.71 | 5800 | |

| 0.22(t66) | |||||||||

| 56177 | 0.17 | 0.17/0.20 | 60 | 48 | ≥800 | 0.635 | 5200 | ||

| 0.22(t66) | |||||||||

| 57177 | 0.17 | 0.17/0.22 | 65.7 | 49.6 | ≥800 | 0.635 | 4550 | ||

| 0.22(t66) | |||||||||

| 64177 | 0.15 | 0.17/0.17 | 70 | 50 | ≥800 | 0.59 | 5200 | ||

| 0.17(t66) | |||||||||

| 8-shed double layer dryer screen | 56188 | 0.17 | 0.18/0.20 | 61.3 | 51.2 | ≥850 | 0.65 | 5700 | |

| 0.20(t66) | |||||||||

| 60188 | 0.18 | 0.19/0.20 | 66 | 49 | ≥900 | 0.68 | 4750 | ||

| 0.20(t66) | |||||||||

| 62188 | 0.15 | 0.16/0.19 | 70.5 | 50.5 | ≥900 | 0.60 | 6200 | ||

| 0.19(t66) | |||||||||

| Weave type | model | Thread diameter(mm) | Density(No.s/cm) | Air permeability (m³/m²h) | |||||

| wap | Weft(top/bottom) | warp | weft | ||||||

| 16-shed two and a half layer dryer screen | CXW324016 | 0.28 | 0.20,0.27/0.40,0.40 | 37-38 | 40-41 | 6000 | |||

| CXW344156 | 0.28 | 0.20,0.27/0.45,0.45 | 37-38 | 31-32 | 6000 | ||||

| CXW384016 | 0.22 | 0.22,0.27/0.40,0.40 | 43-44 | 40-41 | 7500 | ||||

| CXW434106-1 | 0.20 | 0.20,0.25/0.40,0.40 | 48-49 | 42-43 | 7000 | ||||

| CXW434106-2 | 0.20 | 0.20,0.25/0.40,0.4 | 48-49 | 45-46 | 6200 | ||||

| CXW602016-1 | 0.17 | 0.13,0.17/0.20,0.20 | 68-69 | 57-58 | 5500 | ||||

| CXW602016-2 | 0.17 | 0.13,0.17/0.20,0.20 | 38-69 | 61-62 | 5600 | ||||

| CXW603216-1 | 0.17 | 0.13,0.18/0.23,0.23 | 68-69 | 55-56 | 6000 | ||||

| CXW603216-2 | 0.17 | 0.13,0.18/0.23,0.23 | 68-69 | 55-56 | 6500 | ||||

| CXW602516-1 | 0.17 | 0.13,0.18/0.25,0.25 | 68-69 | 51-52 | 6500 | ||||

| CXW602516-2 | 0.17 | 0.13,0.18/0.25,0.25 | 68-69 | 61-62 | 4200 | ||||

| CXW603016-1 | 0.17 | 0.13,0.20/0.30,0.30 | 68-69 | 55-56 | 5000 | ||||

| CXW603016-2 | 0.17 | 0.13,0.20/0.30,0.30 | 68-69 | 58-59 | 4200 | ||||

| CXW603516 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 46-47 | 7500 | ||||

| CXW603516-1 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 49-50 | 6500 | ||||

| CXW603516-2 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 52-53 | 5500 | ||||

| CXW603516-3 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 54-55 | 5000 | ||||

| CXW603516-4 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 55-56 | 4500 | ||||

| CXW603516-5 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 56-57 | 4000 |

||||

Polyester Spiral Dryer Conveyor Wire Mesh Belt For Drying Large Loop

Features of polyester dryer screen

- Install easy to use,interface withou stain,strength can reach 100% normal network

- Adopts imported rubber adhesive side of the net body hard,high temperature is constant,not easy to fold,the characteristics of can adapt to the mevits of different temperature changes.

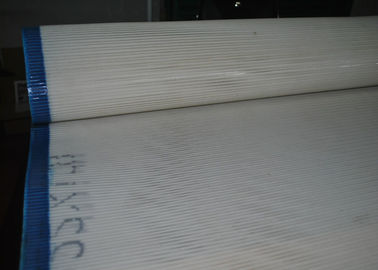

Packing and Delivery

Packing:Plastic bag inside and plywood case outside

Delivery:After receiving the 50% advanced payment,we will arrange to producing and the goods will be shipped within 10days.

Use range

- Slymilk liquid-100-150mesh

- Milk juice-within 250mesh

- Wire-100-200mesh

- Drinking water-300-400mesh

- Paint priner-80-100mesh

- Paint finish-150-200mesh

Specification:

| Polyester Spiral Dryer Conveyor Wire Mesh Belt | ||||

| Weaving Type | Model | Thread Diameter | Air permeability | |

| (mm) | (m3/m2h) | |||

| Warp | Weft | |||

| Large Loop | 4070 | 0.9 | 1.1 | 20000±500 |

| Medium Loop | 3868 | 0.7 | 0.9 | 18500±500 |

| Small Loop | 3252 | 0.52 | 0.7 | 15000±500 |

Paper Making Polyester Dryer Screen / Spiral Wire Conveyor Belt Mesh Customized

Paper Making Polyester Dryer Screen Spiral Conveyor Wire Mesh Belt Description:

Polyester spiral dryer belt is using the latest international in the ninety s made of nonwoven technology and equipment production, is currently the world's one of the most advanced drying, filtering material. I plant the production of polyester spiral stem network is made of high quality high viscosity polyester chip processing wire, after forming, weaving, finishing, finalize the design.

Paper Making Polyester Dryer Screen Spiral Conveyor Wire Mesh Belt Application:

- polyester spiral dryer belt is suitable for high-pressure pressfilter washer, horizontal belt washer, pulp-liquor separator and netting belt coal-washer.

- polyester spiral dryer belt are extensively used for producing cardboard,kraft paper,corrugated paper,paper for train fare,single two-shed press-filter,instead of papermaking machine dry blanket,canvas,as well as apply to colliery,food and medicine as conveyor belts.

- polyester spiral dryer belt are made with special first quality yarns in 100%polyester,every spiral link dryer fabric is heat-set granting a high degree of stability and long running life.

Paper Making Polyester Dryer Screen Spiral Conveyor Wire Mesh Belt Specification:

| Polyester Spiral Dryer Conveyor Wire Mesh Belt | ||||

| Weaving Type | Model | Thread Diameter | Air permeability | |

| (mm) | (m3/m2h) | |||

| Warp | Weft | |||

| Large Loop | 4070 | 0.9 | 1.1 | 20000±500 |

| Medium Loop | 3868 | 0.7 | 0.9 | 18500±500 |

| Small Loop | 3252 | 0.52 | 0.7 | 15000±500 |

Paper Making Polyester Dryer Screen Spiral Conveyor Wire Mesh Belt Features:

- Smooth,seamless filter or conveying surface.

- Durability,Stable property, high strength,good cake release.

- Heat-resistance,high temperature resistance(180 degree).

- Shrink-resistant,wear resistance, acid and alkali-resistant.

- High dimensional and diagonal stability,good air ventilation.

- Filled or unfilled to achieved differing filtration characteristics.

- Super heat with resin sealed edges for lasting,no marking,economical solution .

- Seamless - the seam has exactly the same strength of the belt

- Can be repaired easily on site

Contact Person: Mr.

Tel: 86-318-8097607

Fax: 86-0318-7756677