|

|

- I'm Online Chat Now

polyester mesh fabric

4- Shed Polyester Mesh Fabric Single Layer For Paper Drying Machine

Polyester Mesh Fabric Layer Fabric classification:

Paper making Polyester Mesh Fabric Layer Fabric can be divided into 4-shed, 5-shed, 8-shed, 16-shed, 24-shed according to the weaving type. Single layer, double layer, two-and a half layer fabric and triple-layer fabric are the three common Items.

4-shed and 5-shed series single layer polyester forming fabrics mesh belt are the two widely used polyester forming fabric in paper making, mainly used for producing cultural paper (single glue, double glue and color glue), printing paper, glazed paper, packing paper, common newsprint. Suitable for common fourdrinier paper machine.

8-shed single layer polyester mesh screen belt is suitable for kraft paper, cardboard , corrugated paper making. Also could be used for producing common printing paper. Suitable for common fourdrinier paper machine.

8-shed double layer polyester mesh fabric is suitable for producing quality printing paper. For example ,dictionary paper, offset printing paper, newsprint and wrap paper. It can be used for tissue paper making and the surface pulp, lining pulp, core pulp and bottom pulp of the board paper etc. Suitable for medium and high speed paper making machine.

16-shed double and a half layer polyester forming mesh belt fabric is suitable for producing quality printing paper, such as offset printing paper, copper plate paper, newsprint and cigarette paper series (wrap paper and filter tips paper), Also is could be used for producing toilet paper, tissue paper and surface pulp, lining pulp, core pulp and bottom pulp of the board paper etc. Suitable for medium and high speed paper making machine.

Multi-shed three-layer polyester fabric is suitable for producing quality printing paper, tissue paper and cigarette paper etc. Suitable for high speed paper making machine.

Specificaitons of polyester forming fabric for paper drying:

| polyester forming fabric for paper drying | |||||||||

| Weave type | Model |

Thread diameter (mm) |

Density

(NO./cm) |

strength (N/cm) |

Thickness (mm) |

Air permeability (APm³/m²h) |

|||

| warp | weft | warp | weft | ||||||

| 4-shed single layer dryer screen | 27254 | 0.2 | 0.25 | 30 | 22 | ≥600 | 0.49 | 8000 | |

| 27254-1 | 0.2 | 0.25 | 30 | 23 | ≥600 | 0.495 | 7500 | ||

| 27254-2 | 0.2 | 0.25 | 30 | 24 | ≥600 | 0.50 | 7000 | ||

| 27274 | 0.2 | 0.27 | 30 | 21.5 | ≥600 | 0.51 | 7800 | ||

| 27274-1 | 0.2 | 0.27 | 30 | 22.5 | ≥600 | 0.515 | 7300 | ||

| 31204 | 0.18 | 0.2 | 35 | 28 | ≥600 | 0.43 | 7500 | ||

| 31201-1 | 0.18 | 0.2 | 35 | 30 | ≥600 | 0.43 | 7000 | ||

| 31204-2 | 0.18 | 0.2 | 35 | 30.5 | ≥600 | 0.43 | 6500 | ||

| 5-shed single layer dryer screen | 28205 | 0.2 | 0.2 | 30 | 27.5 | ≥600 | 0.46 | 6800 | |

| 30205 | 0.17 | 0.2 | 32 | 28.5 | ≥500 | 0.41 | 7100 | ||

| 30175 | 0.17 | 0.17 | 32 | 29.5 | ≥500 | 0.39 | 6600 | ||

| 31215 | 0.2 | 0.21 | 35 | 32 | ≥600 | 0.48 | 7000 | ||

| 8-shed single layer dryer screen | 25358 | 0.22 | 0.35 | 28 | 19.5 | ≥700 | 0.85 | 9000 | |

| 25388 | 0.22 | 0.38 | 29.5 | 19 | ≥700 | 0.87 | 8500 | ||

| 27358 | 0.22 | 0.35 | 29 | 20 | ≥700 | 0.85 | 8500 | ||

| 27388 | 0.22 | 0.38 | 31.5 | 19 | ≥700 | 0.87 | 8000 | ||

| 7-shed double layer dryer screen | 50207 | 0.2 | 0.20/0.22 | 54.7 | 36.6 | ≥800 | 0.71 | 5800 | |

| 0.22(t66) | |||||||||

| 56177 | 0.17 | 0.17/0.20 | 60 | 48 | ≥800 | 0.635 | 5200 | ||

| 0.22(t66) | |||||||||

| 57177 | 0.17 | 0.17/0.22 | 65.7 | 49.6 | ≥800 | 0.635 | 4550 | ||

| 0.22(t66) | |||||||||

| 64177 | 0.15 | 0.17/0.17 | 70 | 50 | ≥800 | 0.59 | 5200 | ||

| 0.17(t66) | |||||||||

| 8-shed double layer dryer screen | 56188 | 0.17 | 0.18/0.20 | 61.3 | 51.2 | ≥850 | 0.65 | 5700 | |

| 0.20(t66) | |||||||||

| 60188 | 0.18 | 0.19/0.20 | 66 | 49 | ≥900 | 0.68 | 4750 | ||

| 0.20(t66) | |||||||||

| 62188 | 0.15 | 0.16/0.19 | 70.5 | 50.5 | ≥900 | 0.60 | 6200 | ||

| 0.19(t66) | |||||||||

| Weave type | model | Thread diameter(mm) | Density(No.s/cm) | Air permeability (m³/m²h) | |||||

| wap | Weft(top/bottom) | warp | weft | ||||||

| 16-shed two and a half layer dryer screen | CXW324016 | 0.28 | 0.20,0.27/0.40,0.40 | 37-38 | 40-41 | 6000 | |||

| CXW344156 | 0.28 | 0.20,0.27/0.45,0.45 | 37-38 | 31-32 | 6000 | ||||

| CXW384016 | 0.22 | 0.22,0.27/0.40,0.40 | 43-44 | 40-41 | 7500 | ||||

| CXW434106-1 | 0.20 | 0.20,0.25/0.40,0.40 | 48-49 | 42-43 | 7000 | ||||

| CXW434106-2 | 0.20 | 0.20,0.25/0.40,0.4 | 48-49 | 45-46 | 6200 | ||||

| CXW602016-1 | 0.17 | 0.13,0.17/0.20,0.20 | 68-69 | 57-58 | 5500 | ||||

| CXW602016-2 | 0.17 | 0.13,0.17/0.20,0.20 | 38-69 | 61-62 | 5600 | ||||

| CXW603216-1 | 0.17 | 0.13,0.18/0.23,0.23 | 68-69 | 55-56 | 6000 | ||||

| CXW603216-2 | 0.17 | 0.13,0.18/0.23,0.23 | 68-69 | 55-56 | 6500 | ||||

| CXW602516-1 | 0.17 | 0.13,0.18/0.25,0.25 | 68-69 | 51-52 | 6500 | ||||

| CXW602516-2 | 0.17 | 0.13,0.18/0.25,0.25 | 68-69 | 61-62 | 4200 | ||||

| CXW603016-1 | 0.17 | 0.13,0.20/0.30,0.30 | 68-69 | 55-56 | 5000 | ||||

| CXW603016-2 | 0.17 | 0.13,0.20/0.30,0.30 | 68-69 | 58-59 | 4200 | ||||

| CXW603516 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 46-47 | 7500 | ||||

| CXW603516-1 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 49-50 | 6500 | ||||

| CXW603516-2 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 52-53 | 5500 | ||||

| CXW603516-3 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 54-55 | 5000 | ||||

| CXW603516-4 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 55-56 | 4500 | ||||

| CXW603516-5 | 0.17 | 0.13,0.20/0.35,0.35 | 68-69 | 56-57 | 4000 |

||||

Monofilament 100 Polyester Mesh Fabric Belt Plain Weave For Tailing Disposal

Discription of 06702 Polyester Dryer Screen Belt:

1. the opening size can be 400 micron,500micron,600micron,700micron,800micron,1000micron,1500micron,1800micron,2000micron,2500micron and 3000micron.

2. the width of polyester dryer screen belt mesh is usually 1 meter - 6 meter,the length is available as per requirement

3. edge treatment:the edge of polyester mesh dryer belt can be sealed with glue and cavans

To make sure extra belt durability,polyester Dryer Screen mesh edge treated with glue and cavans.

4. the joining type of polyester plain mesh screen can be endless,steel pin joining,spiral ring joining and pin ring joining.

Endless Seam make sure the seaming points has the same airpermeabilty and strength with the whole belt

Steel pin,pin ring and spiral ring seam are designed for easy and rapid installation.

Features of 06702 Polyester Mesh Dryer Belt:

Polyester Mesh Dryer Belt has features of hard wearing,flat surface,good air permeability,stable property,and long lifespan.

Application of 06702 Polyester Screen Dryer mesh:

Polyester Screen Dryer mesh is widely used in mining sieving,paper pulps making,sulplate pulp packing,mineralseparation,benefication,fiberboard plants.

Polyester Screen Dryer Belt is also used for tailings disposal,colliery,food and medicine.

Specifications of Polyester Dryer Screen Belt mesh

| Polyester Monofilament Dryer Screen Belt | |||||||

| Weaving Type | Model | Thread Diameter | Density(No.s/cm) | Srength | Air Permeability | ||

| (mm) | (N/cm) | (m3/m2h) | |||||

| Warp | Weft | Warp | Weft | ||||

| 2-shed plain weaving fabric | 5802 | 0.75 | 0.8 | 4.7-5 | 4.8-5 | 940 | 20000 |

| 5102 | 1 | 1 | 4.7-5.2 | 4.3-5 | 1600 | 15000 | |

| 6702 | 0.7 | 0.7 | 8 | 7 | 1600 | 11000 | |

| 7102 | 0.7 | 1 | 6.6-7 | 4.3-4.6 | 1100 | 15000 | |

| 8552 | 0.55 | 0.55 | 7.5-8 | 8.5-9 | 850 | 850-6500 | |

| 9452 | 0.45 | 0.45 | 10 | 8.6 | 1600 | 16000 | |

| 9502 | 0.5 | 0.5 | 8.5-9 | 10-10.5 | 750 | 10000 | |

| 12502 | 0.5 | 0.5 | 13.5 | 8.5 | 1800 | 6500 | |

| 3-shed plain weaving fabric | 8603 | 0.5 | 0.6 | 10 | 9 | 1600 | 14000 |

| 8903 | 0.9 | 0.9 | 7.8-8 | 5-5.5 | 2100 | 7500-8500 | |

| 7803 | 0.7 | 0.8 | 8 | 8 | 1600 | 10000 | |

| 20353 | 0.3 | 0.35 | 22 | 14.5 | 1200 | 13000 | |

| 20403 | 0.3 | 0.4 | 22 | 14.5 | 1200 | 13500 | |

High Stretch White 27254 Polyester Dryer Screen Forming Fabric Paper Dryer Mesh

Polyester Dryer Screen Forming Fabric Paper Dryer Mesh classification:

according to weave type: Polyester Dryer Screen belt can be devided into 3 shed,4shed,3-shed polyester dryer screen is suitable for drying papers less than 70g and 4-shed polyester dryer screen fabric is suitable for drying papers more than 70g

according to the form type:polyester forming fabric mesh can be devided into one and a half layer,double layer.

according to thread type:round wire polyester dryer screen and flat wire polyester dryer screen.

Flat wire dryer screen fabric is suitable for the fore hearing box of the drying zone

Description

White 27254 Polyester Dryer Screen Forming Fabric Paper Dryer Mesh has features of good air permeability,easy to clean,the constant working temperature can be 115°C ,and instantaneous high temperature can be 180-220°C.

Polyester Dryer Screen is of abrasion resistantce and long life service,waterprrof.

Packing and shipping:

Polyester Dryer Screen for paper drying can be shiped by courier,by air and by sea.

Usually we pack polyester dryer screen with air bubble film,if ship by sea, it will be packed with plywood case.

Edge treatment of polyester dryer screen:

1. canvas edge treatment

2. glue edge treatment

3. import glue treatment for strict requirement to the edge strength.

4. zip-fastener polyester mesh belt treatment

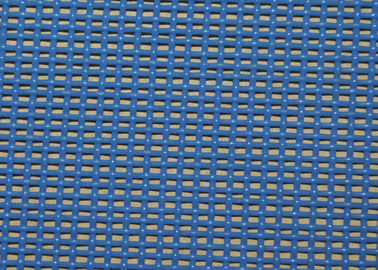

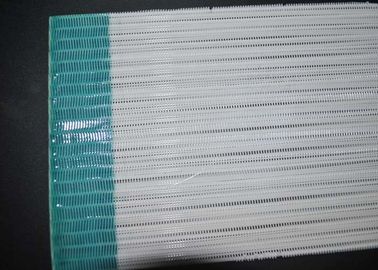

High Strength 100%Polyester Dryer Screen For Conveyor Wire Mesh Belt

High Strength 100%Polyester Dryer Screen For Conveyor Wire Mesh Belt Description:

Polyester spiral dryer belt is using the latest international in the ninety s made of nonwoven technology and equipment production, is currently the world's one of the most advanced drying, filtering material. I plant the production of polyester spiral stem network is made of high quality high viscosity polyester chip processing wire, after forming, weaving, finishing, finalize the design.

High Strength 100%Polyester Dryer Screen For Conveyor Wire Mesh Belt Application:

- polyester spiral dryer belt is suitable for high-pressure pressfilter washer, horizontal belt washer, pulp-liquor separator and netting belt coal-washer.

- polyester spiral dryer belt are extensively used for producing cardboard,kraft paper,corrugated paper,paper for train fare,single two-shed press-filter,instead of papermaking machine dry blanket,canvas,as well as apply to colliery,food and medicine as conveyor belts.

- polyester spiral dryer belt are made with special first quality yarns in 100%polyester,every spiral link dryer fabric is heat-set granting a high degree of stability and long running life.

High Strength 100%Polyester Dryer Screen For Conveyor Wire Mesh Belt Features:

- Smooth,seamless filter or conveying surface.

- Durability,Stable property, high strength,good cake release.

- Heat-resistance,high temperature resistance(180 degree).

- Shrink-resistant,wear resistance, acid and alkali-resistant.

- High dimensional and diagonal stability,good air ventilation.

- Filled or unfilled to achieved differing filtration characteristics.

- Super heat with resin sealed edges for lasting,no marking,economical solution .

- Seamless - the seam has exactly the same strength of the belt

- Can be repaired easily on site

About Our Company:

Anping County PFM Screen Co.,ltd is a professional manufacturer of polyester printing mesh,polyester filter belt and stainless steel mesh.

Our factory is located in Anping County-the famous Wire Mesh Land of China,with a land area of 40,000 square meters,a construction area of 13,000 square meters.PFM factory has 83 sets P7100&P7150 Sulzer polyester printing mesh weaving looms,23 sets Sweden Texo polyester dryer fabric looms,50 sets Japanese GRS1300 wire mesh looms,and 46 sets of other machine and devices including automatic warp arranging machine,heat setting machine,Austria Automatic seaming machine and other test facilities.

PFM is not only professional in field of polyester mesh and stainless steel mesh,but also in wire mesh filters.our strong R&D capability(56 engineers and technicians) enables us to innovate almost everyday.So the customized orders are available.

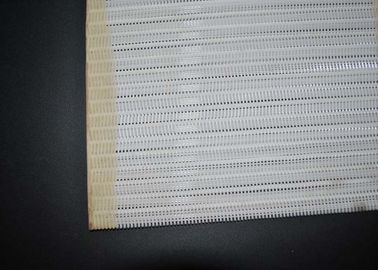

Smooth Surface Stretch Polyester Mesh Fabric Dryer Screen For Wastewater Treatment

Description of polyester dryer screen

Polyester spiral dryer belt is using the latest international in the ninety s made of nonwoven technology and equipment production, is currently the world's one of the most advanced drying, filtering material. I plant the production of polyester spiral stem network is made of high quality high viscosity polyester chip processing wire, after forming, weaving, finishing, finalize the design.

Application of polyester dryer screen

- Dry.Drying the quantitative large wrapping paper culture paper and board paper and pulp board

- Widely used in paper-making,coal mining,food,pharnaceutical,printing and dying,rubber industry.

- Conveyor belt and composite machine mesh belt filter.

Specification:

| Polyester Spiral Dryer Conveyor Wire Mesh Belt | ||||

| Weaving Type | Model | Thread Diameter | Air permeability | |

| (mm) | (m3/m2h) | |||

| Warp | Weft | |||

| Large Loop | 4070 | 0.9 | 1.1 | 20000±500 |

| Medium Loop | 3868 | 0.7 | 0.9 | 18500±500 |

| Small Loop | 3252 | 0.52 | 0.7 | 15000±500 |

Paper Making Polyester Dryer Screen Spiral Conveyor Wire Mesh Belt Features:

- Smooth,seamless filter or conveying surface.

- Durability,Stable property, high strength,good cake release.

- Heat-resistance,high temperature resistance(180 degree).

- Shrink-resistant,wear resistance, acid and alkali-resistant.

- High dimensional and diagonal stability,good air ventilation.

- Filled or unfilled to achieved differing filtration characteristics.

Contact Person: Mr.

Tel: 86-318-8097607

Fax: 86-0318-7756677