|

|

- I'm Online Chat Now

stainless steel mesh conveyor belt

Spiral Stainless Steel Mesh Conveyor Belt / Balanced Weave Belt For Biscuit Baking

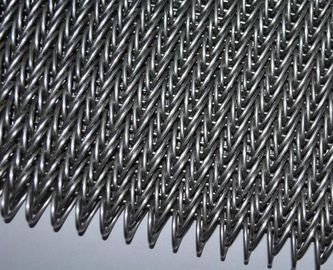

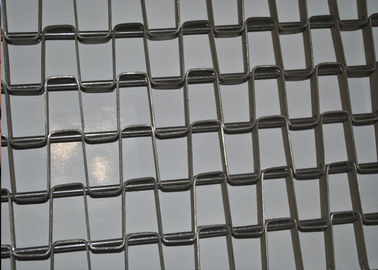

Stainless Steel Compound Balance Weave Wire Mesh Conveyor Belts for Biscuit

This kind of stainless steel wire mesh conveyor belt is also called compand baanced belt,cordweave belt,tight spiral link belt.

According to material wire mesh conveyor belt can be devided into following type:

- stainless steel 304 wire mesh conveyor belt

- stainless steel 316 wire mesh conveyor belt

- 430 wire mesh conveyor belt,310 wire mesh conveyor belt ,2080 wire mesh conveyor belt,which are all high temperature resistant belt

- carbon steel wire mesh conveyor belt galvernized steel wire mesh conveyor belt,which is cheaper than stainless steel material belt,can be used in working environment where there is no corrosion or drying place.

Description

Compound Balance Weave Wire Mesh Conveyor Belts is produced using right and left spiral connecting and crimped connecting rod to form balance weave ,which is tracking streight.

Compound Balance Weave Wire Mesh Conveyor Belts have vey small opening size,which can keep heat for baking material,and it has heavy loading charactors,which can bear big loading.

The round end of spiral wire balanced belt allow goods on it transfer to the following stage processing very easily.

Compound Balance Weave Wire Mesh Conveyor Belts is also can be used to transport in glass furnace,at the same time, it can be use as decorative dividers in architecture and safty curtain

Compound Balance Weave Wire Mesh Conveyor Belts has advantage of positive driving ,running streight charactor

Features of Stainless Steel Compound Balance Weave Wire Mesh Conveyor Belts for Biscuit:

- flat and smooth surface so, the belts can carry small items and unstable products.

- heavy load is available to transport

- processing under pressure is allowed.

- the beit can be used in high temperature environment .

- The belt is widely used in textile products refining and cleaning process.

- high density

- little open area

- The left-wound and right-wound spirals are fitted tightly together alternately and joined with

- Straight rods.

- available in any materials

Advantage of Stainless Steel Compound Balance Weave Wire Mesh Conveyor Belts for Biscuit:

- corrosion resistant,both acid and alkali resistant

- high temperature resistant,can bear 2000 degree centigrade

- long time service

- heavy loading,rod can be added to increase its loading weight.

Heat Resistant Stainless Steel Mesh Conveyor Belt Food Grade For Transport

Type of wire mesh belt:

- stainless steel balanced wire mesh belt

- balance spiral wire mesh belt with chain

- herringbone mesh belt

- horseshoe mesh belt.

- Ladder conveyor belt

Material of wire mesh belt:

stainless steel 304 316 316L 430 310 ,carbon steel galvernized steel and so on.

Description

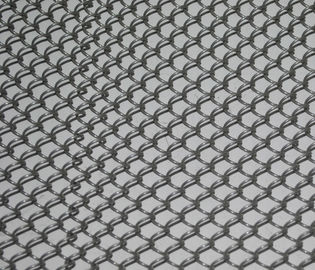

Compound Balanced Weave Belt:

Compound balanced weave belt is also called herringbone belt. It is a variation of the balanced weave, consisting of alternating left&right hand spirals compressed to create a very tight weave with a flat surface. Generally assembled with a straight connecting rod, but is available in limited specifications with a crimped connecting rod.

Honeycomb Belt:

It is also called honeycomb conveyor belt, flat plate conveyor belt. The flat plates are arranged in the form of latice and joined with the straight rods. Customers could require the chain or side plate or chan&side plate attached to flat wire conveyor belt's two sides. The side plate will avoid goods falling down, chain will drive the belt.

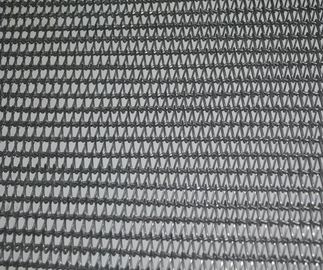

Balanced Weave Belt:

Balanced weave belt, which has big mesh size, strong netting, could bear heavy load.

Spirals usually use the same diameter wires, such as 0.9, 1.2, 1.5, 1.8mm to cross the rod. The rod could be direct wires or waved wires.

Ladder Belt:

Flat flex belting is also calledchocolate conveyor belt, which is made by assembling bent stainless steel wires. This innovative design lasts significantly longer than other flex-style belts:

1. hinges rather than flexing

2. lasts 10X longer than traditional flex-style belts

3. eliminates edge curling, snags and tangling

Features of wire mesh conveyor belt:

- The belt is produced using right and left spiral connecting and crimped connecting rod to form balance weave ,which is tracking streight.

- This kind of spiral wire link belt is the most widely used mesh belt.

- Spiral wirelink belt can conveyor goods from big size or very hot to very small size ,unsorted who need stable support because of its adjustable openning size

- The round end of spiral wirelink belt allow goods on it transfer to the following stage processing very easily.

- spiral wirelink belt is also can be used to transport in glass furnace,at the same time, it can be use as decorative dividers in architecture and safty curtain

| material | such as stainless steel 304,316,316L,310,430 and so on |

| datas | spiral wire diameter,string wire diameter,pitches of spiral wire,string wire,rod daimeter,width and length |

| requriement | such as working temperature,laoding weight.length and width |

| size of the belt | wide and length can be designed according to customer`s requriement. |

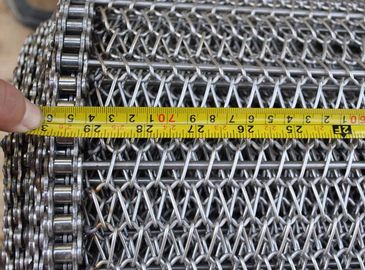

Stainless Steel Balance Wire Mesh Conveyor Belt For Annealing Furnace

Stainless Steel Balance Wire Mesh Conveyor Belt For Annealing Furnace

This kind of stainless steel wire mesh conveyor belt is also called Balanced Spiral Woven Wire Mesh Conveyor Belt ,Spiral Wirelink Wire Conveyor Belt,Chain Driven Belting,Chain Weave Belts,Chain Drive Conveyor Belts

Material of wire mesh Conveyor belt:stainless steel 304 316 430 310 ,carbon steel, galvernized steel and so on

Description

The wire mesh conveyor belt is produced using right and left spiral connecting and crimped connecting rod to form balance weave ,which is tracking streight.

Spiral wire link mesh belt is the most widely used mesh belt.It can conveyor goods from big size or very hot to very small size ,unsorted who need stable support because of its adjustable openning size.

The round end of spiral wire balanced belt allow goods on it transfer to the following stage processing very easily.

spiral wire belt is also can be used to transport in glass furnace,at the same time, it can be use as decorative dividers in architecture and safty curtain

Spiral wire belt with chain has advantage of positive driving ,running streight charactor

The material of the wire mesh belt can be stainless steel 304,316,316L,310,430,2080 ,carbon steel and galvanized steel.

| Name: | Stainless Steel Balance Wire Mesh Conveyor Belt For Annealing Furnace | Application: | Annealing Furnace |

|---|---|---|---|

| Hot Search: | Food Grade Conveyor Belt 36 | Features: | Heat Resistant |

| Type: | Balance Spiral Wire | Certificate: | SGS |

Honeycomb Chain Stainless Steel Mesh Conveyor Belt For Baking Wear Resistance

Type of honeycomb wire mesh conveyor belt

Honeycomb conveyor belt:Flat wire conveyor belt is also called honeycomb conveyor belt,flat plate conveyor belt.The flat plates are arrange in the form of latice and joined with the straight rods.Customers could require the chain or side plate or chain&side plate attached to fiat wire conveyor belt's two sides.The side plate will avoid goods falling down,chain will drive the belt.

Features of wire mesh conveyor belt:

- The belt is produced using right and left spiral connecting and crimped connecting rod to form balance weave ,which is tracking streight.

- This kind of spiral wire link belt is the most widely used mesh belt.

- Spiral wirelink belt can conveyor goods from big size or very hot to very small size ,unsorted who need stable support because of its adjustable openning size

- The round end of spiral wirelink belt allow goods on it transfer to the following stage processing very easily.

- spiral wirelink belt is also can be used to transport in glass furnace,at the same time, it can be use as decorative dividers in architecture and safty curtain

Applications of wire mesh conveyor belt:

- Conveyor machines

- Frying facilities

- Annealing furnaces

- Refrigeration facilities

- Cleaning machines

- Drying ovens

- Food transport

- Baking

- Cooling and freezing

- Steaming and drying

The stainless steel mesh belt installation

- Detemine the pitch of the chain,supporting the corresponding stainless steel sprocket

- Do the overall installation of stainless steel mesh belt

- Stainless steel mesh with the joints installed

- Manual debugging,this process refers to the use of manpower to mobilise the adtive,shaft,until the stainless steel mesh belt adjustment,and then install the corresponding motor and power distribution box.

Before sending inquiry ,the following wire mesh belt information need to be told:

| material | such as stainless steel 304,316,316L,310,430 and so on |

| datas | spiral wire diameter,string wire diameter,pitches of spiral wire,string wire,rod daimeter,width and length |

| requriement | such as working temperature,laoding weight |

| size of the belt | wide and length can be designed according to customer`s requriement. |

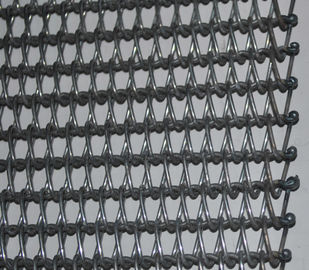

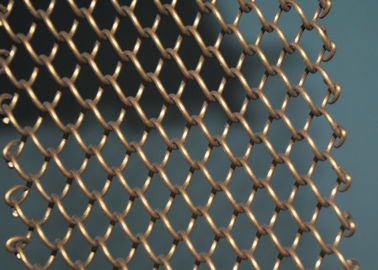

Metal Chain Link Wire Mesh Conveyor Belt For Bakery / Decoration , Light Weight

Metal Conventional Wire Mesh Conveyor Belt For Bakery or Decoration

This kind of stainless steel wire mesh conveyor belt is also called conventional belt,chain link mesh.

Conventional Wire Mesh Conveyor belt has the same way with chain link fencing.

The material of Metal Conventional Wire Mesh Belt can be stainless steel 304.carbon steel,pvc coated ,which is used for decoration,not for food industry.

Description

The wire mesh conveyor belt is produced using right and left spiral wire connecting together to form chain link mesh belt

This kind of conventional Wire Mesh belt can transport lighter material.

Conventional Wire Mesh Conveyor Belt is economic,cheap.

Features of Metal Conventional Wire Mesh Conveyor Belt For Bakery or Decoration:

- Low cost.

- Light weight.

- all of the spiral wires are of the same direction,and woven together

- transporting light products

- simple connections

- open structure

Contact Person: Mr.

Tel: 86-318-8097607

Fax: 86-0318-7756677