|

|

- I'm Online Chat Now

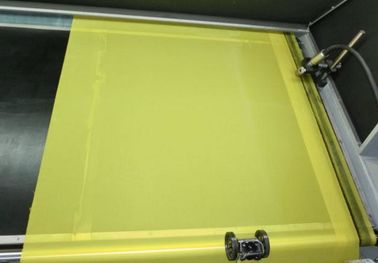

screen printing polyester fabric

Yellow Screen Printing Polyester Fabric For Textile / Glass / PCB / Ceramic Printing

1. Description

Polyester screen printing mesh is woven from yarn that is extruded from heated polyester into a single strand.The extruded thread is the spun to a precise diameter. Conventional monofilament polyester screen fabric will elongate under tension: the higher the tension level, the more the thread can stretch. At excessive tension levels, the thread reaches its "plastic deformation" point, and the screen will no longer hold tension.

2. Application

Polyester was introduced to the screen printing market over 40 years ago and quickly replaced traditional silk as the fabric of choice among screen printers all over the world. It is a material that is uniquely suitable for screen printing of its tensile strength, elastic memory and resistance to chemicals, abrasion heat and moisture. Polyester screen is a kind of synthetic fabric constructed similar to silk, yet with better uniformity. Compared to silk, polyester screen cloth offers extreme durability, yet has a lower price.

| Material: | Polyester | Pattern: | DPP Mesh |

|---|---|---|---|

| Mesh/inch: | 40-600mesh/inch | Color: | White,yellow,black |

| Weave Way: | Plain Or Twill | Supply Type: | In Stock |

| Shipping Port: | Tianjin Or Beijing | Sample: | Free |

Feature advantage

1. Super high tensility and low elongation -all our threads are the best domestic or imported.

2. Standard size, fine mesh-all our workshops adopt international advanced production lines.

3. Nice appearance, flat and soild mesh face, chemical resistance and good screen printing characteristic.

4. Wear resistance, corrosion resistance, high strength and elasticity, heat resistance, acid resistance.

Specification

| COUNT (INCH) | COUNT (CM) | DIAMETER (UM) | OPEPING (UM) | OPEN AREA(%) | THICKNESS(UM) | VOLUME (CM³/CM²) | MAX TEN SION(N/CM) |

| 15 | 6 | 400 | 1270 | 64 | 720 | 460 | 30-60 |

| 18 | 7 | 350 | 1078 | 64 | 640 | 410 | 30-60 |

| 20 | 8 | 300 | 950 | 58 | 550 | 319 | 30-60 |

| 25 | 10 | 250 | 750 | 56 | 620 | 347 | 30-60 |

| 30 | 12 | 250 | 583 | 49 | 450 | 220 | 30-60 |

| 30 | 12 | 150 | 683 | 67 | 300 | 201 | 30-60 |

| 40 | 16 | 200 | 425 | 46 | 400 | 184 | 30-60 |

| 50 | 20 | 80 | 420 | 71 | 120 | 85 | 35-37 |

| 50 | 20 | 150 | 350 | 49 | 260 | 127 | 30-60 |

| 60 | 24 | 100 | 316 | 58 | 136 | 78 | 35-40 |

| 60 | 24 | 120 | 297 | 50 | 240 | 120 | 35-60 |

| 73 | 29 | 120 | 225 | 43 | 240 | 103 | 35-60 |

| 80 | 32 | 64 | 248 | 63 | 95 | 59 | 30-34 |

| 80 | 32 | 100 | 212 | 46 | 200 | 92 | 35-40 |

| 85 | 34 | 100 | 195 | 44 | 221 | 97 | 35-40 |

| 90 | 36 | 100 | 178 | 41 | 216 | 88 | 35-40 |

| 100 | 39 | 55 | 200 | 61 | 88 | 53 | 25-30 |

| 100 | 39 | 80 | 176 | 47 | 150 | 70 | 35-37 |

| 110 | 43 | 80 | 153 | 43 | 130 | 56 | 35-37 |

| 120 | 47 | 55 | 158 | 55 | 88 | 48 | 25-30 |

| 120 | 47 | 71 | 142 | 44 | 135 | 59 | 30-34 |

| 135 | 53 | 55 | 133 | 50 | 86 | 43 | 25-30 |

| 135 | 53 | 64 | 125 | 44 | 100 | 44 | 26-31 |

| 150 | 59 | 64 | 105 | 38 | 100 | 38 | 26-31 |

| 160 | 64 | 55 | 101 | 42 | 98 | 41 | 25-30 |

| 160 | 64 | 64 | 92 | 35 | 120 | 42 | 30-34 |

| 180 | 72 | 48 | 91 | 43 | 78 | 66 | 27-29 |

| 180 | 72 | 55 | 84 | 37 | 100 | 37 | 25-30 |

| 200 | 80 | 48 | 77 | 38 | 74 | 28 | 27-29 |

| 195 | 77 | 55 | 75 | 33 | 105 | 34 | 25-30 |

| 230 | 90 | 48 | 63 | 33 | 85 | 28 | 27-29 |

| 250 | 100 | 40 | 60 | 36 | 70 | 25 | 20-24 |

| 280 | 110 | 40 | 51 | 31 | 85 | 26 | 20-24 |

| 305 | 120 | 40 | 43 | 27 | 68 | 18 | 20-24 |

| 355 | 140 | 34 | 37 | 27 | 58 | 15 | 22-24 |

| 380 | 150 | 31 | 36 | 29 | 46 | 13 | 21-23 |

| 420 | 165 | 31 | 30 | 24 | 46 | 11 | 21-23 |

| 460 | 180 | 27 | 28 | 26 | 56 | 14 | 20-22 |

Polyester Screen Printing Mesh Antistatic High Modulus For Textile / Ceramic Printing

Features of polyester screen printing mesh:

- High tension threshold and breaking point

- high modulus,low elongation monofilament polyester yarn

- Resist to chemicals, abrasion, heat and moisture

- Minimal tension loss during stretching process

- Improved registration due to stable fabric tension

- Good antistatic

- No surface treatment

Specification of polyester screen printing mesh

| COUNT (INCH) | COUNT (CM) | DIAMETER (UM) | OPEPING (UM) | OPEN AREA(%) | THICKNESS(UM) | VOLUME (CM³/CM²) | MAX TEN SION(N/CM) |

| 15 | 6 | 400 | 1270 | 64 | 720 | 460 | 30-60 |

| 18 | 7 | 350 | 1078 | 64 | 640 | 410 | 30-60 |

| 20 | 8 | 300 | 950 | 58 | 550 | 319 | 30-60 |

| 25 | 10 | 250 | 750 | 56 | 620 | 347 | 30-60 |

| 30 | 12 | 250 | 583 | 49 | 450 | 220 | 30-60 |

| 30 | 12 | 150 | 683 | 67 | 300 | 201 | 30-60 |

| 40 | 16 | 200 | 425 | 46 | 400 | 184 | 30-60 |

| 50 | 20 | 80 | 420 | 71 | 120 | 85 | 35-37 |

| 50 | 20 | 150 | 350 | 49 | 260 | 127 | 30-60 |

| 60 | 24 | 100 | 316 | 58 | 136 | 78 | 35-40 |

| 60 | 24 | 120 | 297 | 50 | 240 | 120 | 35-60 |

| 73 | 29 | 120 | 225 | 43 | 240 | 103 | 35-60 |

| 80 | 32 | 64 | 248 | 63 | 95 | 59 | 30-34 |

| 80 | 32 | 100 | 212 | 46 | 200 | 92 | 35-40 |

| 85 | 34 | 100 | 195 | 44 | 221 | 97 | 35-40 |

| 90 | 36 | 100 | 178 | 41 | 216 | 88 | 35-40 |

| 100 | 39 | 55 | 200 | 61 | 88 | 53 | 25-30 |

| 100 | 39 | 80 | 176 | 47 | 150 | 70 | 35-37 |

| 110 | 43 | 80 | 153 | 43 | 130 | 56 | 35-37 |

| 120 | 47 | 55 | 158 | 55 | 88 | 48 | 25-30 |

| 120 | 47 | 71 | 142 | 44 | 135 | 59 | 30-34 |

| 135 | 53 | 55 | 133 | 50 | 86 | 43 | 25-30 |

| 135 | 53 | 64 | 125 | 44 | 100 | 44 | 26-31 |

| 150 | 59 | 64 | 105 | 38 | 100 | 38 | 26-31 |

| 160 | 64 | 55 | 101 | 42 | 98 | 41 | 25-30 |

| 160 | 64 | 64 | 92 | 35 | 120 | 42 | 30-34 |

| 180 | 72 | 48 | 91 | 43 | 78 | 66 | 27-29 |

| 180 | 72 | 55 | 84 | 37 | 100 | 37 | 25-30 |

| 200 | 80 | 48 | 77 | 38 | 74 | 28 | 27-29 |

| 195 | 77 | 55 | 75 | 33 | 105 | 34 | 25-30 |

| 230 | 90 | 48 | 63 | 33 | 85 | 28 | 27-29 |

| 250 | 100 | 40 | 60 | 36 | 70 | 25 | 20-24 |

| 280 | 110 | 40 | 51 | 31 | 85 | 26 | 20-24 |

| 305 | 120 | 40 | 43 | 27 | 68 | 18 | 20-24 |

| 355 | 140 | 34 | 37 | 27 | 58 | 15 | 22-24 |

| 380 | 150 | 31 | 36 | 29 | 46 | 13 | 21-23 |

| 420 | 165 | 31 | 30 | 24 | 46 | 11 | 21-23 |

| 460 | 180 | 27 | 28 | 26 | 56 | 14 | 20-22 |

Tips of Best polyester screen printing mesh for work:

- 20 and 40 mesh is used mostly for glitter inks that need a very open mesh for printing.

- 60 mesh is usually used for printing smaller glitter and most shimmer inks.

- 80 mesh is also used for printing shimmer inks and for laying down thick layers of ink for high-density printing. It also works well for printing foil adhesive.

- 110 mesh makes printing white and other thick inks easy. It is ideal for spot color printing since it holds less detail than 155 mesh and lays down a thick layer of ink for maximum coverage.

- 120 mesh is one of the most rifely mesh sizes in screen printing. It works great for printing white ink and other colored inks that have a thicker viscosity.

- 155 mesh is great for general purpose textile printing with basic to semi-fine detail. It will hold a little finer detail than a 110 mesh while also working well with thinner inks.

- 200 mesh is great for printing more detailed prints that need a thinner layer of ink than a 155 mesh. It works very well with thinner inks and is a good middle-range mesh size.

- 230 mesh is great for high-end fine detail printing. A 230 mesh can hold halftones very well and also lets a little more ink through then a 305 mesh. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning.

- 280 mesh screens are great for high-end fine detail printing. A 280 mesh can hold halftones very well and also lets a little more ink through then a 305 mesh.

- 305 mesh holds extremely high detail, letting through only a thin layer of ink. This allows for a very soft hand on the garment and is great for use in printing halftones and process prints. The yellow color prevents light from reflecting through the threads of the mesh and keeps a sharper image when burning.

White And Yellow Screen Printing Polyester Fabric Mesh Twill Weave FDA Certificate

Feature advantage

- .Screen printing can transfer thick ink deposits and creat special effects,so 30mesh/inch to 300mesh/inch silk screen printing mesh is widely used to print high quality commercial garments.

- Any ink deposits and any ink system are possible with screen printing,so silk screen printing mesh is widely used to print knitted fabric,blankets,silk even coarse denim.

- Screen printing offers many superiorities of ink transparency,ink briliance,various decorative pattern choice,and fast production cycle time,so silk screen printing mesh is perferred for CDs and DVDs printing process.

- Silk screen printing mesh is also used for glass printing,such as pharmacy glass appliance,home appliance( microwaves oven), Automotive glass(black mask for the front,side and back windows),glass containers(perfumes,cosmetics,drink bottles).

- Screen printing can print the chanllenging intense colors and ornate decor on ceramics,so silk screen printing mesh is extensively used in the decoration of dishes,tiles,earthenware or fine china.

- Silk screen printing mesh is the fastest and most economical method to print printed circuit boards(PCB)solder masks,etching resist,legends and single or multi-layers.

Specification

| COUNT (INCH) | COUNT (CM) | DIAMETER (UM) | OPEPING (UM) | OPEN AREA(%) | THICKNESS(UM) | VOLUME (CM³/CM²) | MAX TEN SION(N/CM) |

| 15 | 6 | 400 | 1270 | 64 | 720 | 460 | 30-60 |

| 18 | 7 | 350 | 1078 | 64 | 640 | 410 | 30-60 |

| 20 | 8 | 300 | 950 | 58 | 550 | 319 | 30-60 |

| 25 | 10 | 250 | 750 | 56 | 620 | 347 | 30-60 |

| 30 | 12 | 250 | 583 | 49 | 450 | 220 | 30-60 |

| 30 | 12 | 150 | 683 | 67 | 300 | 201 | 30-60 |

| 40 | 16 | 200 | 425 | 46 | 400 | 184 | 30-60 |

| 50 | 20 | 80 | 420 | 71 | 120 | 85 | 35-37 |

| 50 | 20 | 150 | 350 | 49 | 260 | 127 | 30-60 |

| 60 | 24 | 100 | 316 | 58 | 136 | 78 | 35-40 |

| 60 | 24 | 120 | 297 | 50 | 240 | 120 | 35-60 |

| 73 | 29 | 120 | 225 | 43 | 240 | 103 | 35-60 |

| 80 | 32 | 64 | 248 | 63 | 95 | 59 | 30-34 |

| 80 | 32 | 100 | 212 | 46 | 200 | 92 | 35-40 |

| 85 | 34 | 100 | 195 | 44 | 221 | 97 | 35-40 |

| 90 | 36 | 100 | 178 | 41 | 216 | 88 | 35-40 |

| 100 | 39 | 55 | 200 | 61 | 88 | 53 | 25-30 |

| 100 | 39 | 80 | 176 | 47 | 150 | 70 | 35-37 |

| 110 | 43 | 80 | 153 | 43 | 130 | 56 | 35-37 |

| 120 | 47 | 55 | 158 | 55 | 88 | 48 | 25-30 |

| 120 | 47 | 71 | 142 | 44 | 135 | 59 | 30-34 |

| 135 | 53 | 55 | 133 | 50 | 86 | 43 | 25-30 |

| 135 | 53 | 64 | 125 | 44 | 100 | 44 | 26-31 |

| 150 | 59 | 64 | 105 | 38 | 100 | 38 | 26-31 |

| 160 | 64 | 55 | 101 | 42 | 98 | 41 | 25-30 |

| 160 | 64 | 64 | 92 | 35 | 120 | 42 | 30-34 |

| 180 | 72 | 48 | 91 | 43 | 78 | 66 | 27-29 |

| 180 | 72 | 55 | 84 | 37 | 100 | 37 | 25-30 |

| 200 | 80 | 48 | 77 | 38 | 74 | 28 | 27-29 |

| 195 | 77 | 55 | 75 | 33 | 105 | 34 | 25-30 |

| 230 | 90 | 48 | 63 | 33 | 85 | 28 | 27-29 |

| 250 | 100 | 40 | 60 | 36 | 70 | 25 | 20-24 |

| 280 | 110 | 40 | 51 | 31 | 85 | 26 | 20-24 |

| 305 | 120 | 40 | 43 | 27 | 68 | 18 | 20-24 |

| 355 | 140 | 34 | 37 | 27 | 58 | 15 | 22-24 |

| 380 | 150 | 31 | 36 | 29 | 46 | 13 | 21-23 |

| 420 | 165 | 31 | 30 | 24 | 46 | 11 | 21-23 |

| 460 | 180 | 27 | 28 | 26 | 56 | 14 | 20-22 |

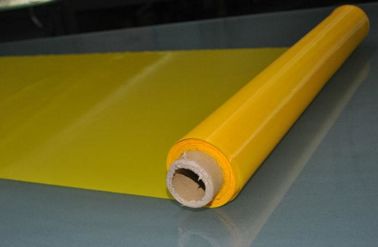

Plain Weave 165T Screen Printing Fabric Mesh , Monofilament Polyester Mesh

Description

- Mesh count: 6T~165T

- Material: 100% polyester monofilament

- Weave type: Plain

- Color: white, Yellow, black

- Width: 42",45",50",53",57",62",65",74",86",90",120",130",width available (width as order will be ok also)

- Standard length: 30m/roll,50m/roll. (Cut length as order will be also available)

- Theoretical ink: 6.5-128 cm3/m2

Feature advantage

- Any ink deposits and any ink system are possible with screen printing,so silk screen printing mesh is widely used to print knitted fabric,blankets,silk even coarse denim.

- Screen printing offers many superiorities of ink transparency,ink briliance,various decorative pattern choice,and fast production cycle time,so silk screen printing mesh is perferred for CDs and DVDs printing process.

- Silk screen printing mesh is also used for glass printing,such as pharmacy glass appliance,home appliance( microwaves oven), Automotive glass(black mask for the front,side and back windows),glass containers(perfumes,cosmetics,drink bottles).

- Silk screen printing mesh is the fastest and most economical method to print printed circuit boards(PCB)solder masks,etching resist,legends and single or multi-layers.

Application

| Credit Cards | 150T/380-31;120T/300-34;100T/255-34;71T/180-55 |

| Dashboards | 165T/420-31;150T/380-31;140T/355-31;120T/300-34;110T/280-34um;90T/230-48;36T/90-100 |

| Ceramic Tiles | 165T/420-31;150T/380-31;140T/355-31;120T/300-34;100T/255-40;77T/195-55;62T/160-64; |

| 43T/110-80;36T/90-100;32T/83-100;12T/30-150 | |

| Glass | 165T/420-31;150T/380-31;140T/355-31;120T/300-34;100T/255-40;90T/230-48;77T/195-48; |

| 62T/160-64;68T/175-55;43T/110-80; | |

| Textiles | 150T/380-31;140T/355-31;120T/300-34;100T/255-40;77T/195-48;62T/160-64;54T/137-64; |

| 47T/120-55;43T/110-80;40T/100-80;36T/90-100;32T/83-100;16T/40-200;12T/30-150 | |

| Objects | 165T/420-31;150T/380-31;140T/355-31;120T/300-34;100T/255-40 |

High Tension 64um Polyester Screen Printing Mesh Roll 54T For Electronics Printing

Features of polyester screen printing mesh:

- High tension threshold and breaking point

- high modulus,low elongation monofilament polyester yarn

- Resist to chemicals, abrasion, heat and moisture

- Minimal tension loss during stretching process

- Improved registration due to stable fabric tension

- Good antistatic

- No surface treatment

Description

| name | high tension 54T Polyester Screen Printing Mesh For Electronics Printing |

| mesh count per cm | 54 |

| thread diameter | 64 |

| color | white |

| opening size | 121micron |

| width | 115cm,127cm,136cm,145cm,157cm,165cm,188cm,220cm and MAX width can be 3.65cm. |

Our factory introduction

Anping County PFM Screen Co.,Ltd is located in the famous "home town of wire mesh" -Anping county industrial park, covers an area of 40000 square meters, construction area of 11000 square meters, It has 10000 grade clean production workshop 1500 square meters, employees 163 people, engineering technical personnel 56 people.Introduced the world's most advanced polyester screen printing mesh production line including Switzerland 330 cm p7100 gripper loom, German intelligent electronic sectional warping machines, automatic heat setting machine, washing machine and other equipment of 46.Has the most advanced test equipments.

Contact Person: Mr.

Tel: 86-318-8097607

Fax: 86-0318-7756677